Many prismatic machining contracts are ideally fulfilled on a 5-axis machining centre, which enables components to be produced cost effectively. It is because the two rotary axes are able to position the component quickly and automatically in various orientations for milling and drilling, without the need for expensive fixtures and multiple set-ups by hand. A problem arises, however, if the components being produced do not command a high selling price, as most 5-axis plant tends to be expensive and investment often cannot be justified.

Subcontractor G&J (CNC) Services in Paddock Wood has apparently found a solution – the Leadwell V-30iT 3+2-axis BT40 machining centre from WH-Lead, Towcester. The entry-level price of less than six figures belies the 5-axis machine’s extensive capabilities. The hourly rate that the subcontractor charges based on the investment allows less complex prismatic components to be produced efficiently at prices that compare favourably with those quoted by competitors in low-wage countries.

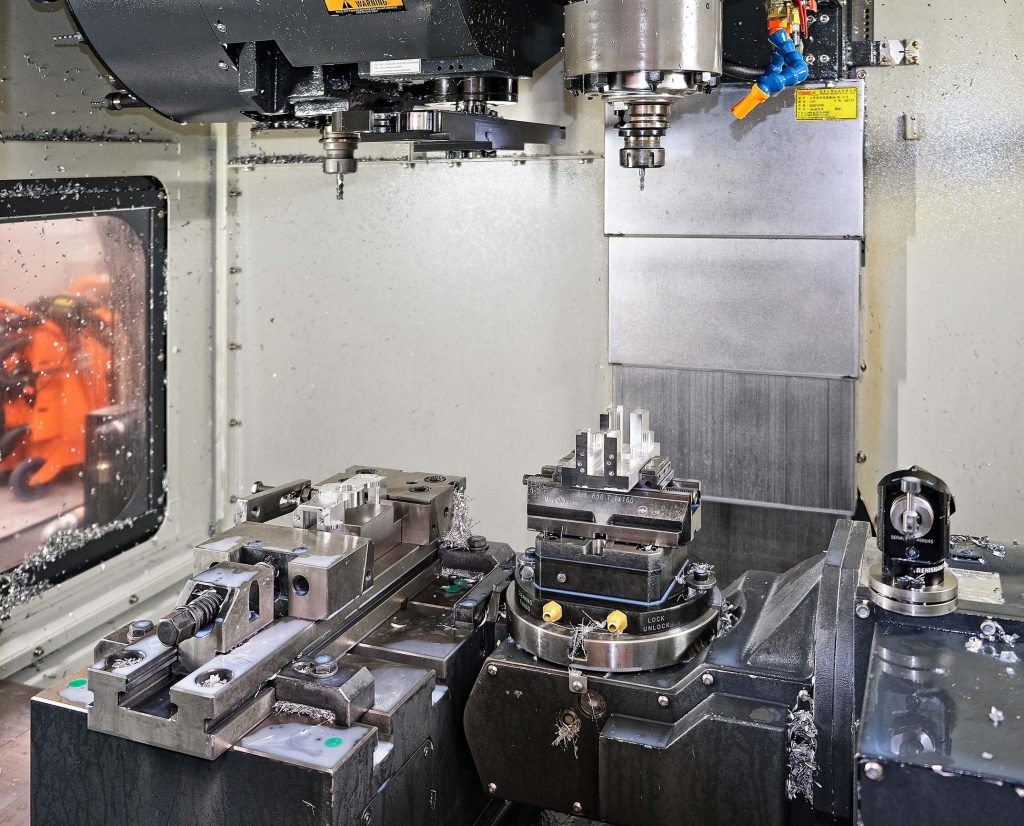

Of novel configuration, the V-30iT has a 205 mm diameter rotary table mounted on a swivelling trunnion driven from one side. It is supported on the other side not by a simple bearing block, but by a similar unit built into the side of a 450 x 300 mm fixed table. It is unusual on a machine that is already inexpensive to find such a major addition. The fixed table can be used to complete a 3-axis operation on a part weighing up to 50 kg before it is transferred to the rotary table. By that time, the part must weigh no more than 35 kg if it is to undergo machining at up to 45 degrees tilt, or 25 kg if the trunnion position is steeper.

The owner of G&J (CNC) Services, Charlie Naismith, is in a good position to comment on the merits of the Taiwanese-built machine compared with more expensive, fully interpolating 5-axis machining centres of German and Japanese origin used at his other four engineering sites in the south-east of England. The group of companies, CTN Group, boasts around 100 CNC machine tools of which 10 are 5-axis models.

Mr Naismith said, “Depending on the value of the parts being machined, which is normally down to their complexity and the material used, you have to make sure the figures add up. Much of our throughput is fairly simple 3+2-axis work in mild steel and aluminium that customers will not pay a premium for, so the Leadwell machine is perfect.

“Actually we use it in 3-axis mode for much of the time, but the 5-axis functionality is there for when we need it, saving costs associated with workholding, handling and work-in-progress. At the same time it helps with accuracy by being able to access parts with shorter tools and by cutting down on manual refixturing.”

He also appreciates the ergonomics of the V-30iT, pointing out that the rotary table when flat is at the same level as the fixed table, so there are no clearance issues. The machine is also well specified, with 800 mm of X-axis travel, 460 and 387 mm travels in Y and Z, roller bearing guideways, a 12,000 rpm spindle, a 24-position tool magazine with 1.8 seconds cutter exchange and 48 m/min rapids in X and Y, 36 m/min in Z.

Control is provided by a Fanuc 0i-MF Plus CNC system, although Siemens, Fagor and Heidenhain are optional, as are specification of 4+1 or full 5-axis interpolation. Another benefit of 3+2 CNC apart from the lower cost, according to Mr Naismith, is that engineers in the Paddock Wood factory can step up to 5-axis machining and build a portfolio of new work around the enhanced capability, while taking advantage of the extra 3-axis capacity for regular work.

The first Leadwell machine, which was also G&J (CNC) Services’ first 5-axis machine, was installed in 2021. Its purchase was prompted by the need to produce a particular agricultural industry component that would not have been feasible to put onto a 3-axis machine.

A second, identical machining centre followed a year later to provide extra capacity and equipment redundancy. Both machines were available ex-stock from WH-Lead’s Towcester showroom and delivered within a fortnight, together with Renishaw tool and workpiece probing, Filtermist extraction and a post processor for the subcontractor’s OneCNC CADCAM system. WH-Lead’s customary high level of ongoing after-sales service and support is being provided.

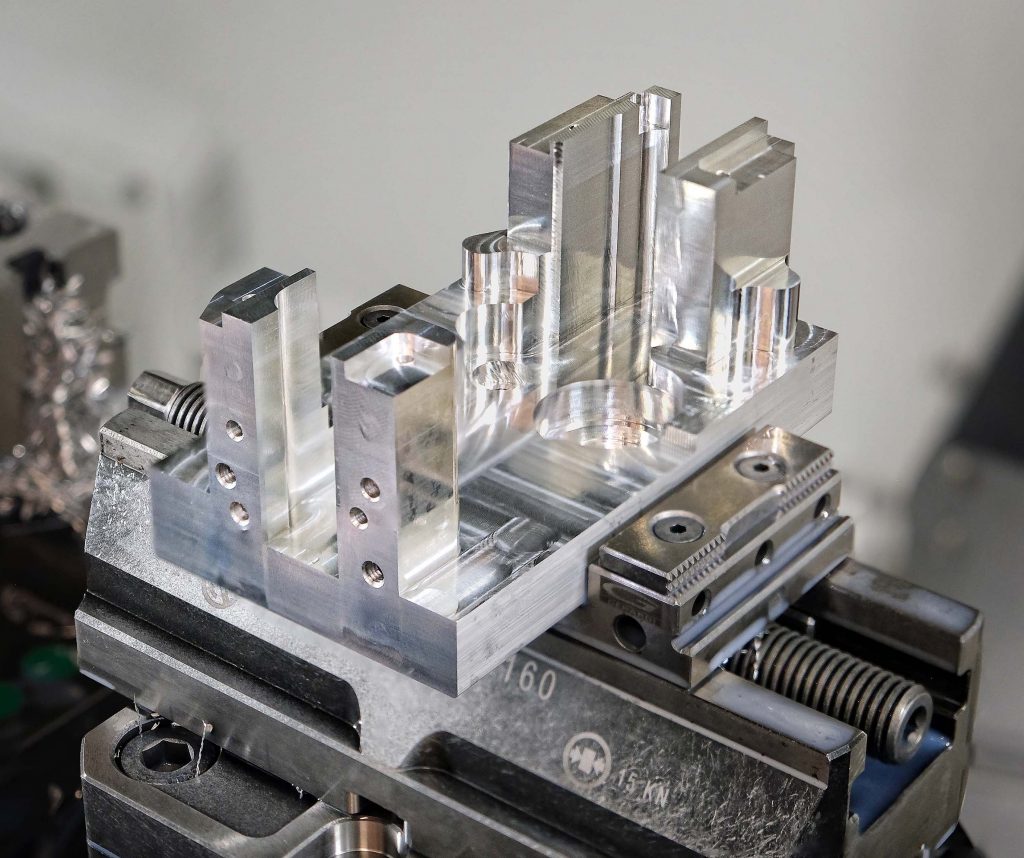

Generally speaking, parts that previously required four or five separate operations are now produced in two, sometimes without leaving the V-30iT if pre-machining is done on one of the tables. A typical component cited by Mr Naismith for a fluid transfer equipment manufacturer is produced in this way, resulting in a 30 percent shorter floor-to-floor time compared with when it was produced in four operations on different 3-axis machines.

A further advantage of the new process route is that operator walk-away intervals are longer, allowing more meaningful work to be performed elsewhere in the factory while machining is in progress. As a result, it is likely that more and more jobs at G&J (CNC) Services will be transferred to the 5-axis plant as time progresses.